Reviving Aging Infrastructure

Environmental Impact

The infiltration and exfiltration of wastewater from deteriorated and broken sewer lines pose a significant threat to the environment. The EPA reports that SSOs can contaminate surface waters with pathogens, harmful nutrients, and other pollutants, endangering aquatic life and compromising water quality. SSOs contribute to the degradation of ecosystems, disrupt the balance of aquatic habitats, and harm wildlife populations.

Public Health Concerns

The EPA notes that children are at a greater risk from water contaminants due to their developing immune systems and increased likelihood of exposure. The presence of pathogens and viruses in untreated sewage presents grave public health risks, including gastrointestinal illnesses, respiratory infections, and other serious health effects. Additionally, elderly individuals and those with weakened immune systems are more susceptible to waterborne diseases transmitted through contaminated waterways.

Community Disruption

The traditional method of sewer repair, which typically requires extensive excavation, not only disrupts the daily lives of citizens but also imposes significant challenges on local businesses. Trenching operations often result in road closures, traffic diversions, and disturbances to both residential and commercial areas, exacerbating community frustration and inconvenience.

The Cost and Impact of I&I

According to the EPA, the cost of collecting and treating wastewater typically falls between $2 to $5 per thousand gallons. If a community experiences an annual I&I volume of 150 million gallons, it could incur expenses ranging from $300,000 to $750,000 per year for transporting and treating the flow at treatment plants.

Repairing & Protecting Storm & Sewer Systems

PipePatch

- A No-Dig Solution: Complete trenchless repairs quickly, reducing downtime and minimizing site disturbance.

- Cost Saving: Save on labor, equipment, and restoration with targeted repairs versus traditional excavation.

- A Permanent Solution: Creates a structural repair stronger than the original pipe.

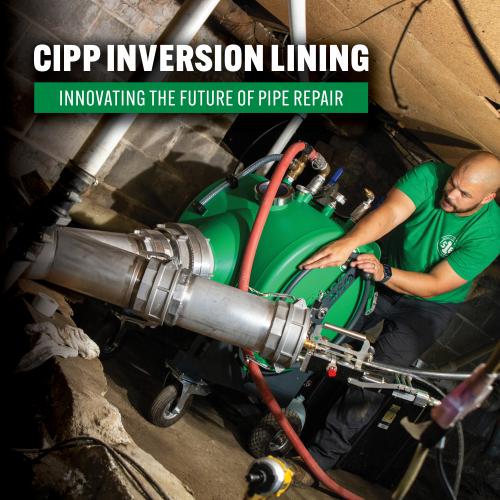

CIPP Lining

- A No-Dig Solution: Complete trenchless repairs quickly, reducing downtime and minimizing site disturbance.

- Cost Saving: Save on labor, equipment, and restoration with targeted repairs versus traditional excavation.

- A Permanent Solution: Creates a structural repair stronger than the original pipe.

Cementitious Mortars

- Revitalization and Longevity: Extends the life and critical integrity of the sewer system.

- Cost-Effective Rehab: Reduces inflow and infiltration, addressing up to 30% of issues through manhole rehabilitation.

- Rapid Water Control: Delivers quick, high-strength repairs to stop water and infiltration in minimal time.

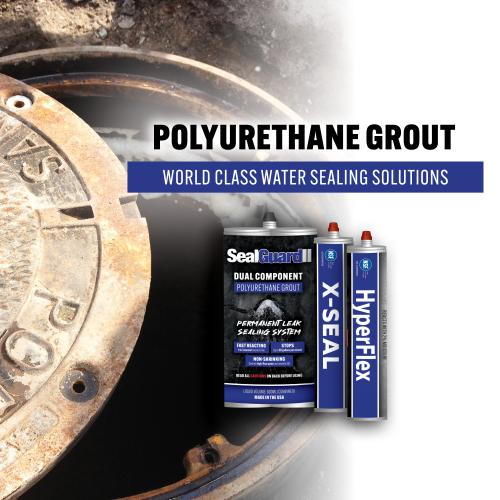

Grouts

- Water Control: Offers options for both rapid water control and slower-setting applications.

- Versatile Applications: Suitable for both preventative and reactive water control.

- Trusted Formulas: Delivers quick, high-strength repairs to stop water and infiltration in minimal time.

Epoxies

- Water Control: Offers options for both rapid water control and slower-setting applications.

- Versatile Applications: Suitable for both preventative and reactive water control.

- Trusted Formulas: Delivers quick, high-strength repairs to stop water and infiltration in minimal time.

New England, being one of the first parts of the country settled, has some of the oldest infrastructure. This is no different for the Town of Hull, MA. Recently the town put out a multi-million-dollar sewer rehabilitation bid for CIPP, which also included extensive manhole and structure rehabilitation. This sanitary sewer infrastructure was only 45 years old and is certainly not as old as other sewer systems in New England. Hull is a coastal community with high brackish ground water and minimal pipe grades, so hydrogen sulfide has been an issue in the collection system, which has increased the rate of deterioration of the system.

The Town’s 36-inch RCP sanitary sewer interceptor exhibited both corrosion of the concrete due to the presence of hydrogen sulfide gas and infiltration due to high groundwater. This was also the case in the precast concrete manholes on the project. The work included trenchless technologies such as cured-in-place lining of 10,000 ft. of 36-inch gravity piping, grouting of service connections as well as the rehabilitation of over 1,000 vertical feet of precast manhole structures. Also included was the rehabilitation of a 4-barrel inverted siphon, 2-barrel lagoon crossings and the concrete structures associated with them. All of the work proposed was required to be completed utilizing trenchless technologies.

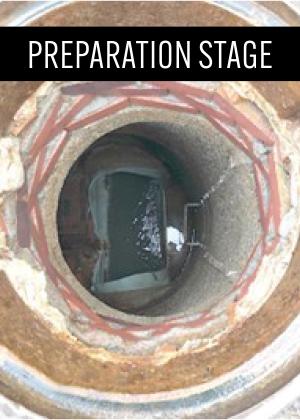

Preparation

Preparation involved stopping infiltration, pressure washing the walls to a sound substrate, and addressing corrosion with exposed aggregate.

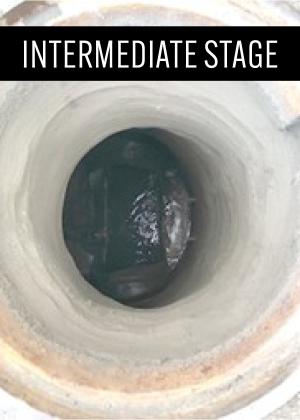

Rehabilitation

Leaks were sealed and patching completed with Strong-Seal® QSR. A ½ inch layer of Strong-Seal® High Performance Mix was applied.

Completion

The final epoxy was applied at the end to ensure a durable finish.

The project specifications also called for the rehabilitation of the manhole inverts. All inverts needed to be scheduled when the manholes were bypassed for the CIPP lining unless the liner went through the manhole invert. Other manholes without a CIPP liner needed to have the inverts bypassed with flow through plugs. For the remaining portion of the manhole work, the crews had to go back to each manhole and complete the preparation, infiltration elimination, cementitious coating, and epoxy lining.