Homeowners facing a non-functional century-old farmhouse bathroom find a cost-effective, non-disruptive solution to severe clogging and deteriorating pipes, sidestepping excavation, and ensuring a lasting fix.

Situation

Residing in a century-old farmhouse, homeowners faced a plumbing crisis that disrupted their daily lives. One of their bathrooms had become non-functional, due to severe clogging and backups. This inconvenience forced the occupants to use the shower in one bathroom and the toilet in another. The situation escalated when they discovered that their cast iron pipes were deteriorating and a slight misalignment in pipes had formed at the foundation, a problem diagnosed by a plumber. The proposed solution was excessively high in cost: a complete pipe replacement, leaving the homeowners helpless and seeking a more practical option.

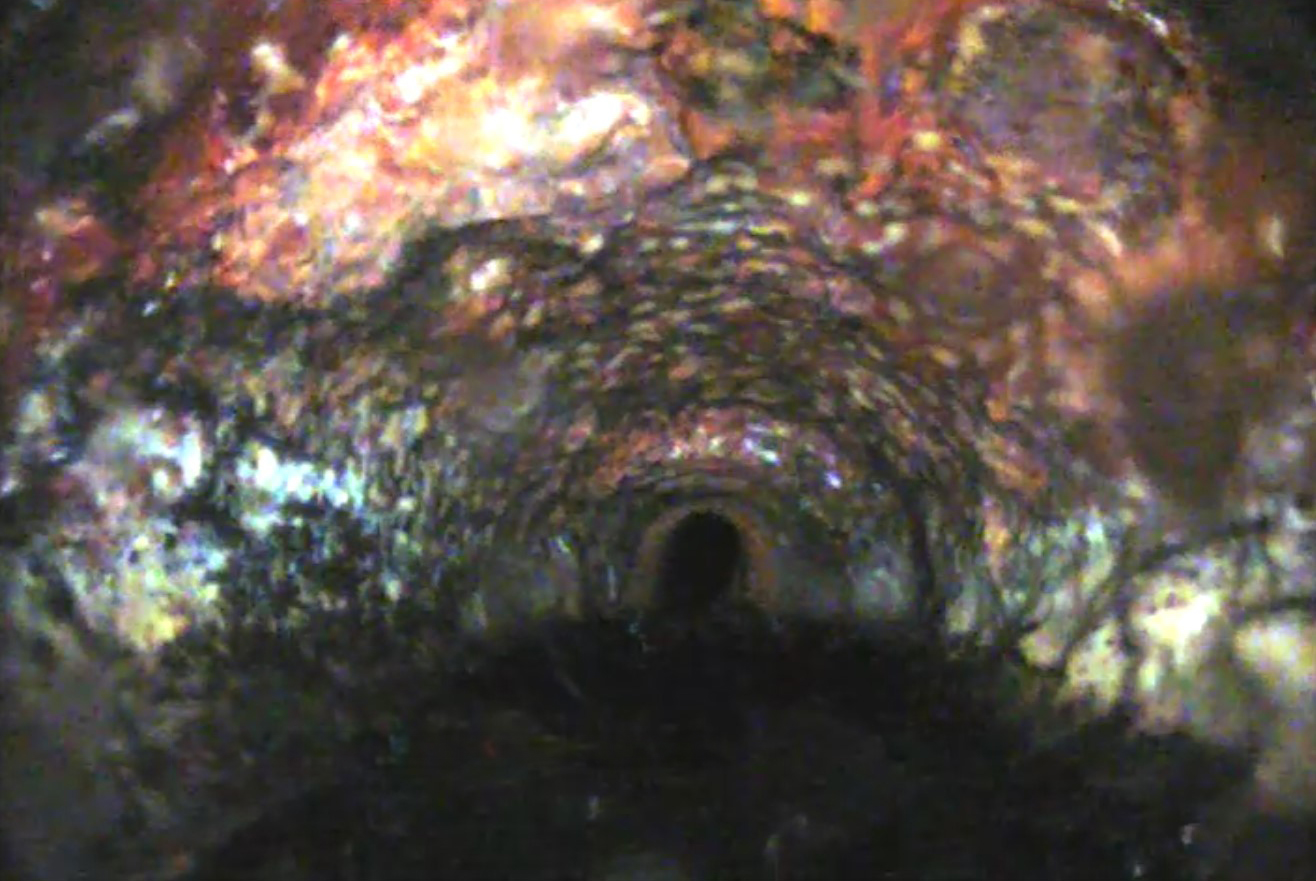

Deteriorating cast Iron pipes and blockage causing severe clogging and backups.

An Alternative Solution

Months went by when a visiting friend mentioned they had heard about a no-dig alternative to traditional excavation. Intrigued by the prospect of a cost-effective, trenchless solution, the homeowners did some research and explored their possibilities. After exploring a few websites and making a handful of phone calls, the homeowners found a glimmer of hope in the PipePatch® spot repair system by Source One Environmental (S1E).

Solution

S1E connected the homeowner with a contractor who assessed the issue by utilizing a CCTV camera to inspect the line in advance and recommended The PipePatch® XTEND system for the primary issue. Available for 3”-10” diameter pipes, PipePatch® XTEND is a longer spot repair solution than standard 24” and 48” patches, featuring an extra-long packer and complete push-in-place or pull-in-place liner kit. By eliminating the necessity for excavation, the PipePatch® XTEND addressed the core issues by creating a new pipe within the cast iron pipes without disrupting the homeowner's property. This non-intrusive approach not only reduced costs significantly but also provided a sustainable, long-lasting solution to the homeowners' plumbing problems.

Prepping the XTEND Packer - Spot repairs offer faster solutions, targeting specific damage without the extensive downtime.

Process

To execute the repair, the contractor and S1E Training Team planned and implemented a step-by-step process, ensuring precision and efficiency. First, the pipes were inspected and then underwent thorough cleaning using a Picote Mini Miller Machine equipped with cleaning chains and brushes. This crucial step prepared the pipes for the subsequent repair, eliminating any debris and buildup, ensuring the effectiveness of the patching process. For the primary repair, the team installed (2) PipePatch® XTEND Kits, each measuring 10 feet. Due to the confined access points, the XTEND patches were preferred over traditional CIPP lining methods. This strategic decision ensured the successful rehabilitation of the deteriorating pipeline, resolving the homeowner's concerns effectively. The team then utilized the Mini Miller again as it played an integral role in reinstating one of the branches that connected to the lateral. Using the reinstatement cutter and sanding paddles, the team skillfully restored the lateral connection, providing a seamless integration into the repaired pipeline.

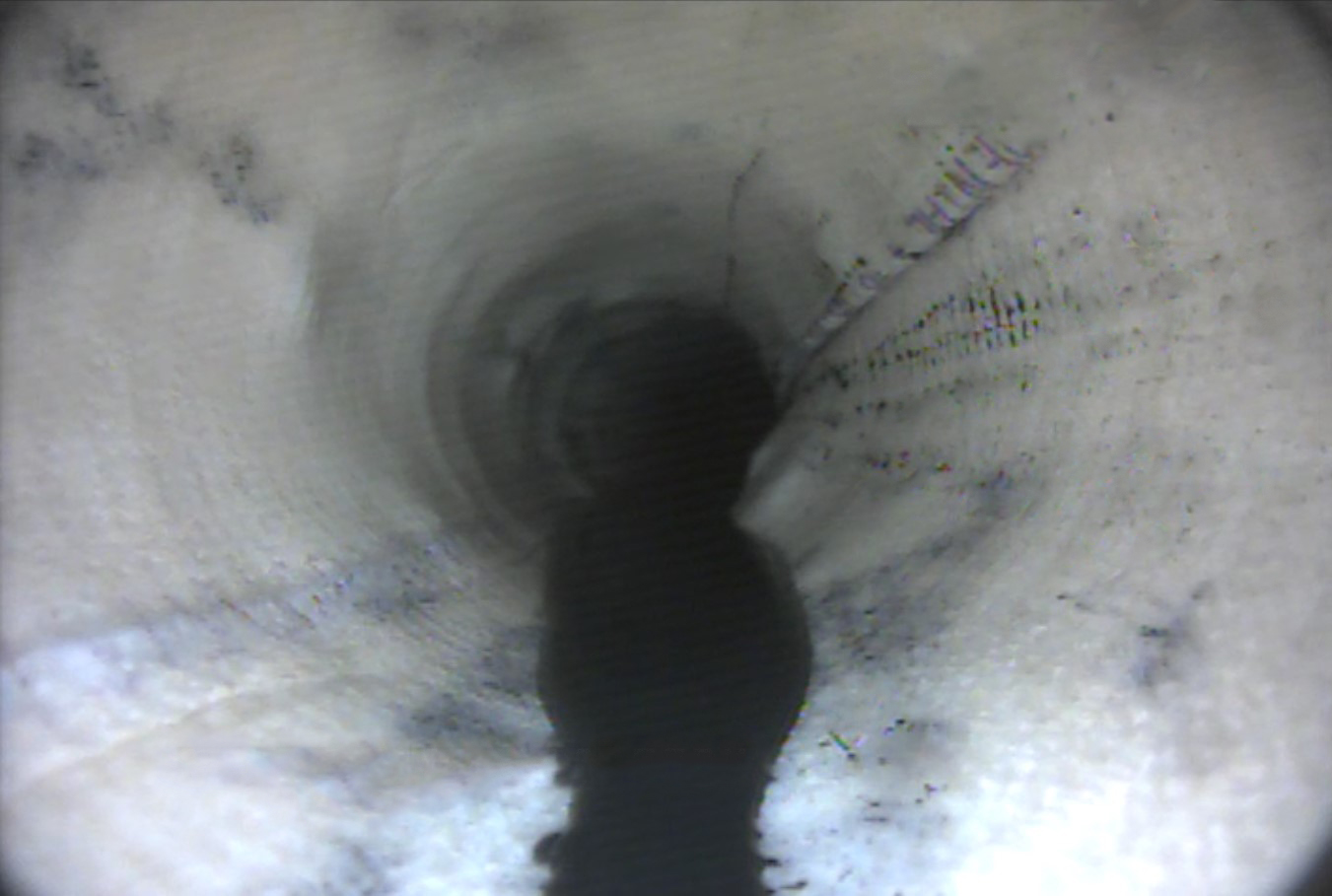

The PipePatch XTEND prior to installation - Spot repairs maintain the original diameter of the pipe, which is crucial to maintaining the flow capacity of the pipe.

Challenges and Results

Traditionally, repairing longer runs of pipe, specifically with CIPP lining, especially in confined spaces, required extensive equipment and logistical challenges. However, the PipePatch® XTEND redefines the approach, enabling repairs for runs up to 45 feet with just a few patches. This streamlined process significantly reduces the complexity of the repair, making it an efficient and effective solution for homeowners and professionals alike. One of the primary advantages over traditional CIPP pipe lining lies in the minimal equipment requirements. With CIPP lining, substantial investments are needed in equipment such as drums, wet-out tables, and various curing systems like hot water, steam, and UV. In contrast, the PipePatch® XTEND simplifies the process. Utilizing a packer and the PipePatch® XTEND kit featuring a fiberglass tube and silicate resin, repairs become straightforward, eliminating the need for extensive, costly equipment setups. Another notable benefit of the PipePatch® XTEND is its adaptability to limited spaces. In instances like the this where the only access point was a small basement cellar, the PipePatch® XTEND proved indispensable. It could be effortlessly carried to the access point and pushed or pulled into place, inflated to the appropriate PSI, and left in position until the cure time was met. This simplicity contrasts sharply with the challenges faced during traditional CIPP lining, where maneuvering drums and other equipment near the access point can be difficult. Moreover, the PipePatch® XTEND offers the flexibility of both summer and winter resins. Ambient cured silicate kits can enable faster curing than traditional CIPP lining systems, such as hot water and steam. In the discussed project, the pipes were cleaned, and one patch using winter resin was installed in the morning. After lunch, the second XTEND Patch was seamlessly installed. This efficient use of time showcases the advantage of the XTEND system, ensuring minimal disruption to the homeowner's daily routine and fewer trips to the job site for the contractor.

Deteriorating pipe fully restored with PipePatch XTEND Spot Repair, creating a new pipe within. Service now fully operational.

Conclusion

In the face of a challenging plumbing dilemma, the homeowners of the century-old property found a lifeline in the PipePatch® XTEND. This innovative technology not only rescued them from exorbitant costs and disruptive excavations but also provided a permanent solution to their plumbing challenges. By embracing such groundbreaking solutions and implementing precise techniques, communities can navigate the challenges of aging infrastructure with confidence, ensuring the longevity and functionality of essential plumbing systems while minimizing disruption and costs. The PipePatch® XTEND, coupled with the expertise of skilled professionals, stands as a testament to the power of innovation, transforming challenges into opportunities and heralding a better tomorrow for homeowners facing similar predicaments.